- Call Now

-

905-648-8200

- [email protected]

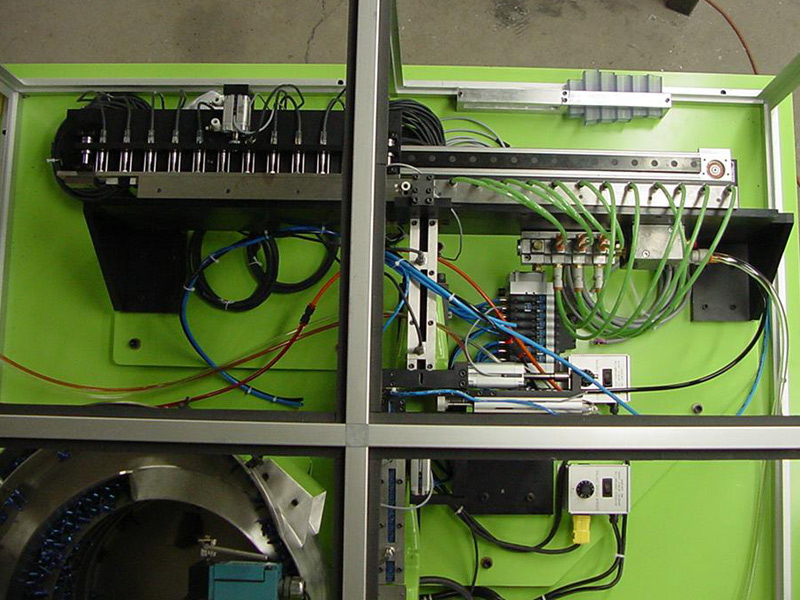

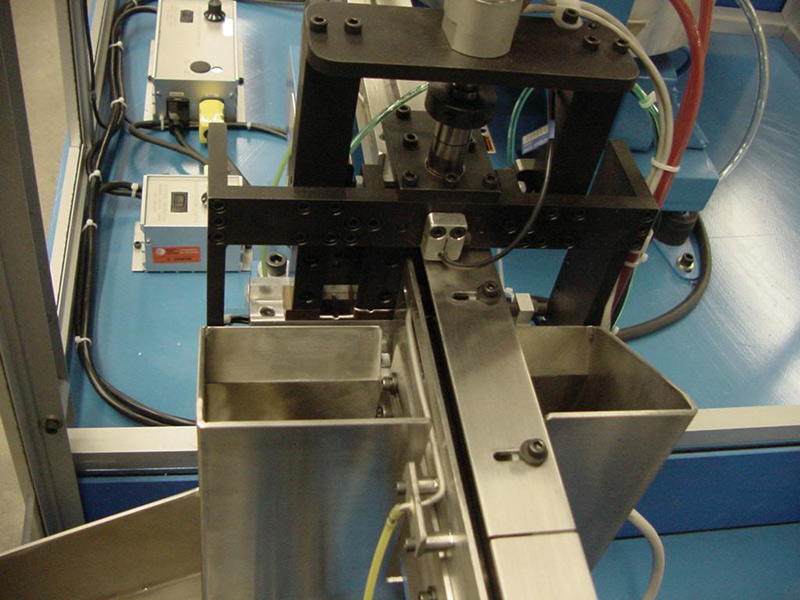

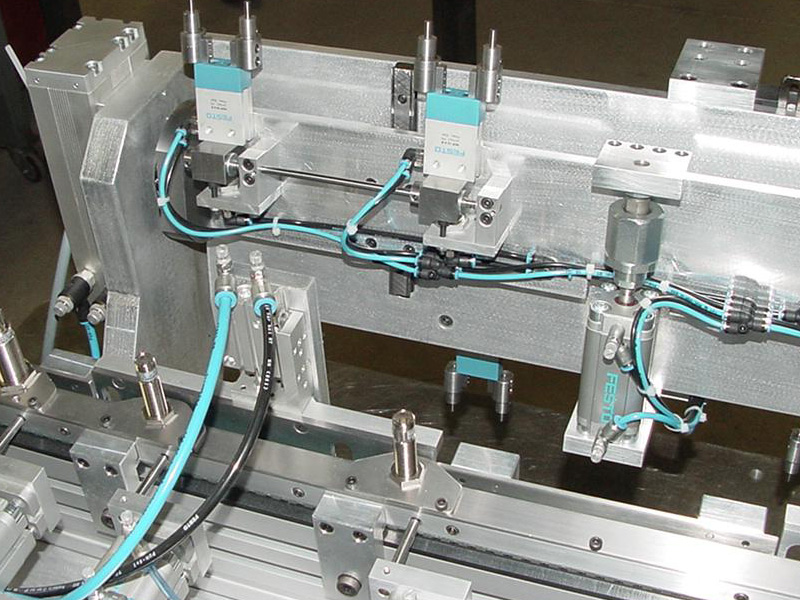

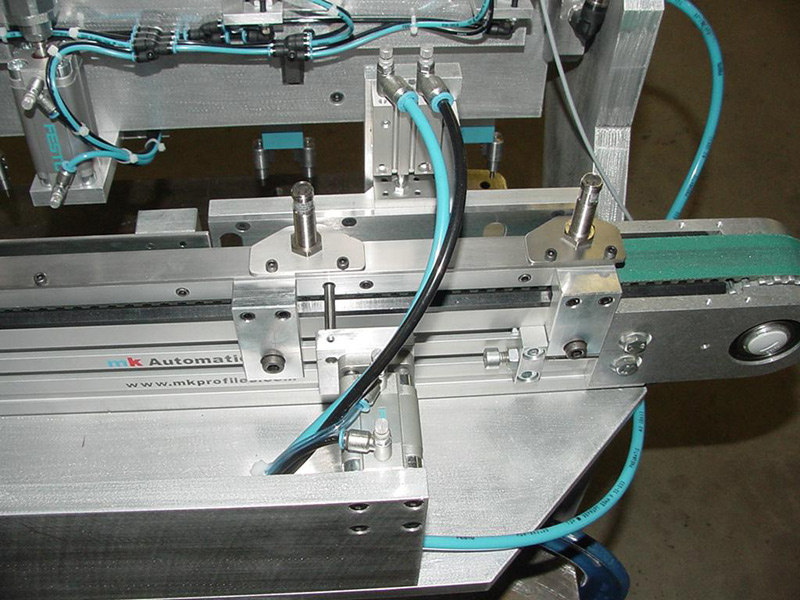

Escapements and Nests

Escapements and presentation nests

For many projects a blow feed system may be most useful. Singulated, oriented parts can be released and blown through round or custom extruded flexible hoses. Doing so allows oriented parts to be delivered to machine locations that may not have been otherwise accessible. Multiple discharges can be provided.

With pick and place or robotic part handling applications, we are able to build and integrate single part presentation nests. On demand, oriented parts are suitably separated from the flow of parts, to allow for a gripper to locate and grip, and remove them. Part present sensing is applied whenever possible to communicate the nest condition with the machine control.

Nesting of oriented parts for manual removal by an operator can often be justified as a quality improvement aid as well as a labour reduction tool.

Should there be an application which requires a high degree of "on the bench" development for part insertion, you may wish to consider Autofeed to build prototype tooling.

The process

When purchasing an Autofeed system there are many things to be considered. It is in both our best interests to help you through each of the steps:

Determine the best orientation to suit your application and to obtain the most reliable results from a feed system. Specify the required rate to meet your production needs.

Take the orientation and rate information and ascertain the most suitable type and configuration of feed system to meet your needs.

Propose to you, through a quotation, the equipment, price and realistic delivery.

Receive and process the order. Provide you, in a timely manner, with a cad generated layout drawing requesting at that time such outstanding details as purchased item manufacturers name, paint colour, and sample parts.